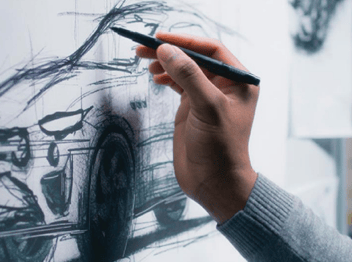

Built with purpose.

Designed for your mission

“Performing all of planning, research, design, production, test · evaluation, and A/S based on customer-tailored development know-hows.“

From development to support

Independent R&D Organization with Complete Vehicle Development Capabilities

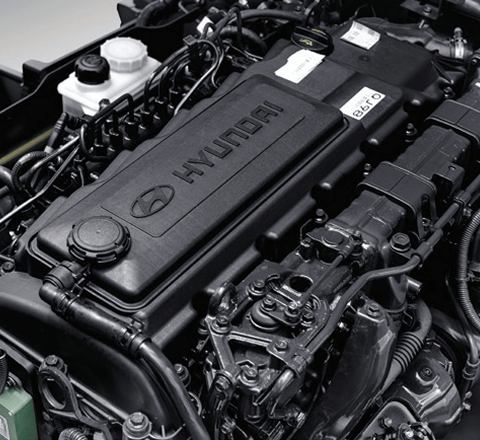

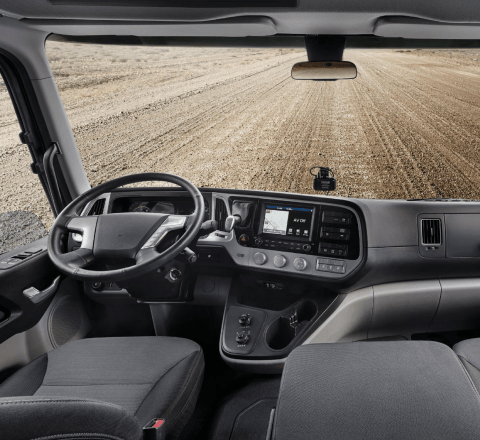

Kia Special Vehicle Division operates as an independent R&D organization with complete vehicle development functions, especially the one and the only military vehicle development R&D organization in Korea. The entire process of vehicle development, from planning and system development to design, prototype, vehicle test, homologation, and integrated product support (IPS) based on customer needs, is performed within the division, and offers customized vehicles with state-of-the-art technology and finish through the collaboration infrastructure within Hyundai Motor Group and outside network with private research organizations.

Special Vehicle Division

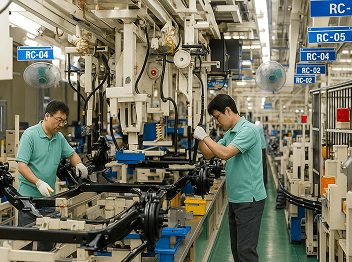

Vehicle Development

-

Product Planning

- PM (Project Manager)

- Discovering commercial deriv ative solution

- Managing investment budget

-

System Developmen

- System Integration/Layout design

- M&S/VPG durability and structural analyses

-

Detail Design

- System review/Detail design

- Controller/Electric design

- System solution development

-

Prototype

- In-house prototype production / Vehicle assembly

- Parts, processes, complete car inspection test

-

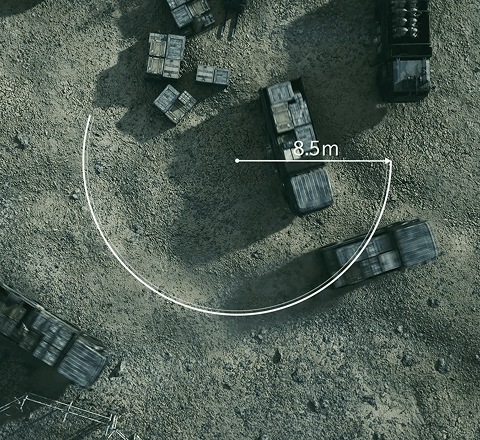

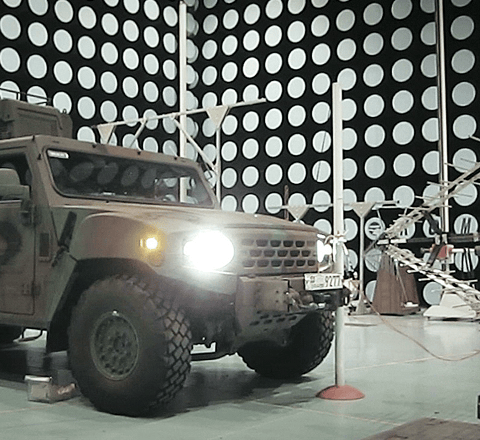

Vehicle Test

- Vehicle function /performance/ Electromagnetic tests

- Durability test/Government

-

Homologation

- Legal and environmental analyses

- Environmental/safety verifications in Korea & abroad

-

IPS*

- LSA, RAM-applied logistic support

- Development of 12 elements of IPS

* IPS : Integrated Product Support

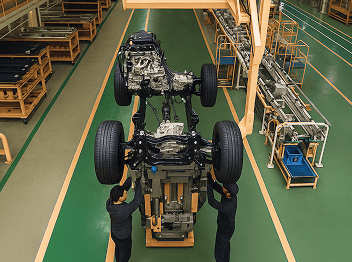

Special Vehicle Division

External Collaboration Infrastructure

External Infrastructure

-

Development Infrastructure at Hyundai / Kia Namyang R&D Center

- Development Infrastructure at Hyundai / Kia Namyang R&D Center

-

Core part developmentusing the group affiliates

- Hyundai Transys : Transmission/axle development

- Hyundai Rotem : Generator development, etc.

-

Using government testing infrastructure

- ADD Startup test center : Unpaved/field durability test, etc.

-

Homologation

- KATECH : Collaboration in hydrogen fuel cell vehicle development

-

External supplier collaboration

- Development using supplier’s parts such as cargo box